Electrical and mechanical equipment tend to heat up before they fall, hiding from sight until a problem becomes "self-evident". Fortunately, thermal imaging cameras instantly make those hot spots clearly visible so you can catch them in time to investigate further and plan repairs before they turn critical. Scan electrical cabinets, breaker panels, fuses, switchgear, pumps and motors with a thermal imager and get an instant picture of impending trouble that you likely would miss otherwise.

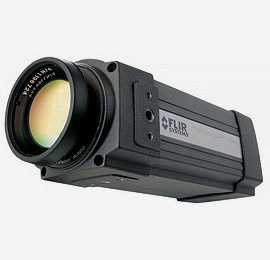

FLIR thermal imaging cameras are ideal for a wide range of automation applications when flexibility and unequaled performance are vital such as in automated inspections, process control and condition monitoring combining thermal and visual cameras in small, affordable packages, providing continuous temperature monitoring and alarming for uninterrupted condition monitoring of critical electrical and mechanical equipment.

Meet the new next generation FLIR ONE Pro thermal cameras. When connected to a smartphone, the FLIR ONE allows you to see the world in a whole new way. Whether you're into outdoor adventures and DIY home repairs, or are a hardworking professional looking for the convenience of a thermal camera that goes everywhere you do, there's a FLIR ONE Pro for you with advanced image processing that brings out more detail in every image, so problems won't go undetected. Plus, they're proof of a job well done.

If it can be measured, FLIR has a tool for the job with multimeters, clamp meters, insulation testers, voltage detectors and horoscopes. And now introducing the power of "Infrared Guided Measurement" (IGM) together with a range of electrical measurement features, so you can visually identify electrical problems and solve complex issues quickly. With IR resolutions up to 19,200 pixels, you'll see temperature differences that indicate the start of electrical faults before they become serious issues.

Thermal imaging inspections are non-destructive and do not interrupt day-to-day operations. An IR camera can detect problems and areas of concern that cannot be detected with a visual inspection, such as loose connections, faulty or overloaded circuit breakers and imbalanced loads in substations, transformers, swtichgear and discconnects.

Optical gas imaging is becoming the standard for industrial gas leak detection. Infrared-based inspection has numerous advantages over tradition volatile compound detection methods. Not only is it faster and more efficient, but also it offers numerous safety benefits. Inspectors are able to perform surveys from a great distance, avoiding exposure to potentially hazardous chemicals.

Test results on circuit breakers by NETA (InterNational Electrical Testing Association) show over a 15% failure rate. Defective circuit breakers, motor contactors and protective relays fail because they are mis-wired or broken. Trip linkages fail because of dust, hardened grease, corrosion and misalignment. The current-carrying parts and main contacts fail because they have been damaged by fault interruption or operating springs have fatigued so they no longer provide adequate opening and closing force.

Thermal imaging is an effective tool in an electrical or mechanical distribution system predictive maintenance program. A thermal imaging scan increases confidence in equipment, decreases the potential for fire loss, reduces high-energy costs and helps avoid business interruption as well as satisfy your insurance provider’s requirements.

Infrared Systems has for the past 20 years been offering contract inspections for the manufacturing, mining, energy exploration, construction and petrochemical industry. Inspections include on-site inspections with follow-up reports including anomalies detected and recommended repair suggestions.